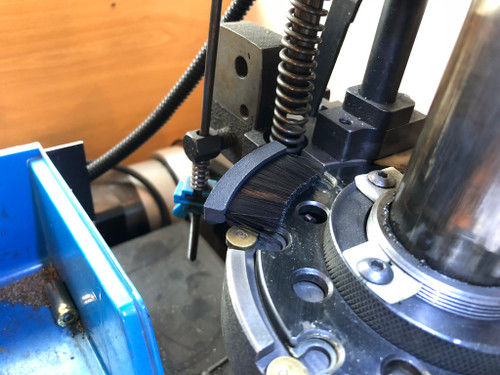

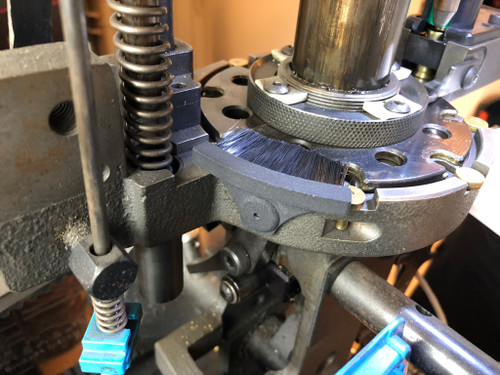

Mark 7 Reloading DecapSense for Dillon Precision 1050

Sometimes you decap and sometimes you don't (decapping is the process in Station #2 that pushes out the old primer). What happens when your decapping pin is broken and you don't realize it ? How about that stubborn spent primer that hangs onto the pin and isn't fully discarded only to be pushed back in by the swage station ? oops.

This is a must-have accessory for the Mark 7® 1050 Autodrive. The positive decap sensor uses optical recognition to determine if a spent primer is removed and if no spent primer falls the machine stops after the stroke making easy to remove the impacted case. Save yourself and save your machine. If you are processing or loading new brass, simply disable the sensor from the Mark 7® tablet interface. ALSO acts as a brass sensor - when enabled can stop the press when brass is not present in the decapping station.

A critical safety and productivity measure, this sensor can dramatically reduce injuries, downtime and machine breakage. Ships with the sensor, mounting bracket, and clear tubing and an e-mail file that will update your machine's software. If purchased with a new machine this will be installed and tested for you.

If you are installing on an existing Mark 7® 1050 Autodrive simply use the existing hardware and hole on your machine and remove the spent primer cup that came with you machine. No more emptying cups. No more overflowing cups. Concentrate on your operations. This is only available for users of the Mark 7® 1050 Autodrive.